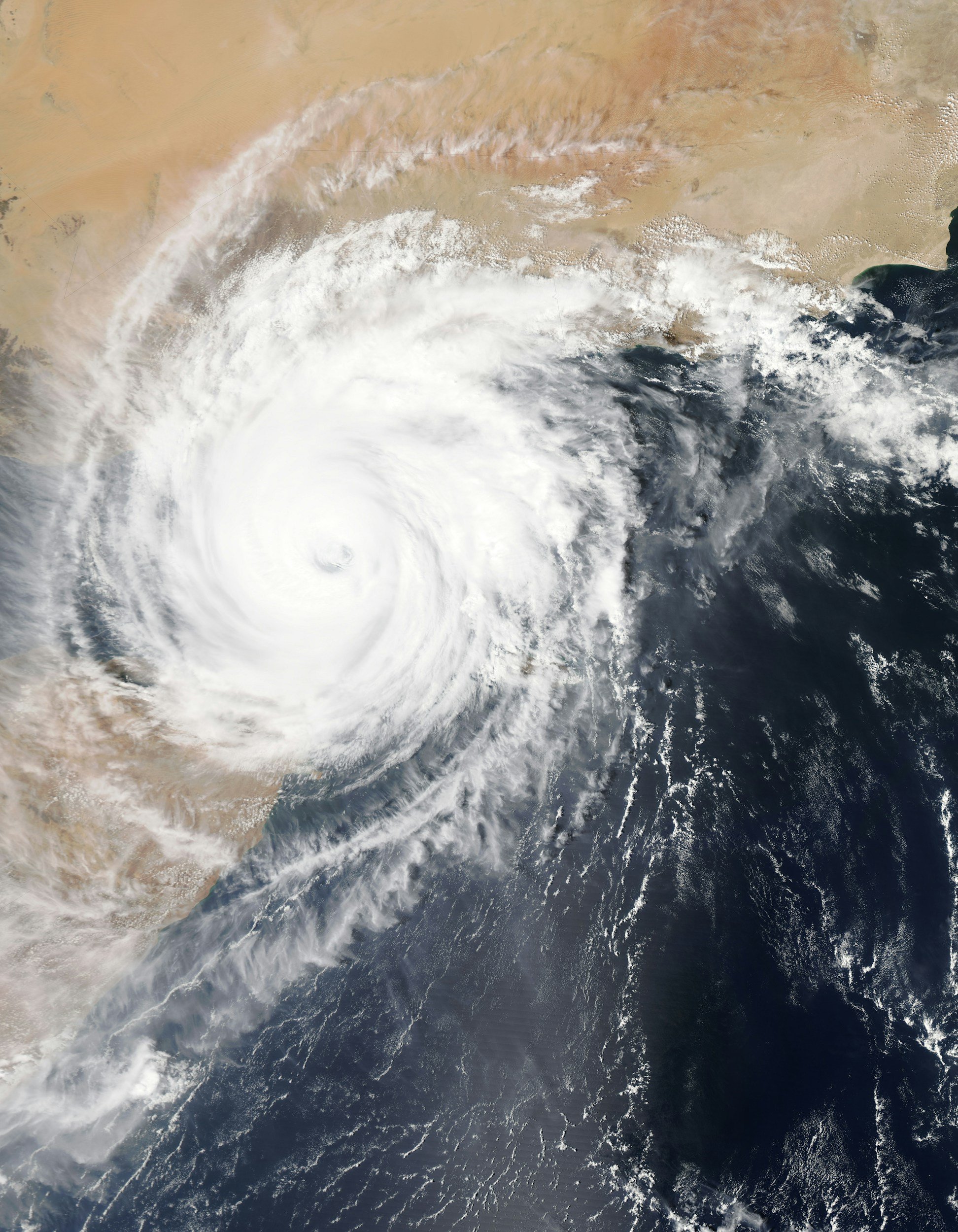

HURRICANE PREPAREDNESS-RESPONSE PLAN

It is company policy to stop or delay construction activities, 24 to 48 hours prior to landfall

depending on the project’s geographical distance from our closest shop/yard. The only

exception would be for any activity related to prepping or securing the job site for the coming

storm.

Read More

SKIN CANCER

The sun is essential to all life on Earth, however, too much exposure to the sun can be harmful to us. Excessive exposure to ultraviolet light, also called UV rays, emitted from the sun can many skin conditions as well as skin cancer.

Read More

Scaffolding

It's a terrible thing to realize that hardly a workday goes by without a construction worker falling off a scaffold to his death. And those who survive scaffold falls are often crippled for the remainder of their lives.

These tragedies are sometimes caused by faulty design or poor construction. But in most cases, the basic cause is poor maintenance or improper use - something that you can do something about.

Read More

NOT MY PROBLEM

We have all heard someone say in the workplace, “it is not my problem” or “that is not my job”. They may have been referring to a coworker not following rules, someone doing a task wrong, or a hazard left by someone in the work area. Regardless of what the circumstances are, all of these scenarios affect everyone in the company.

Read More

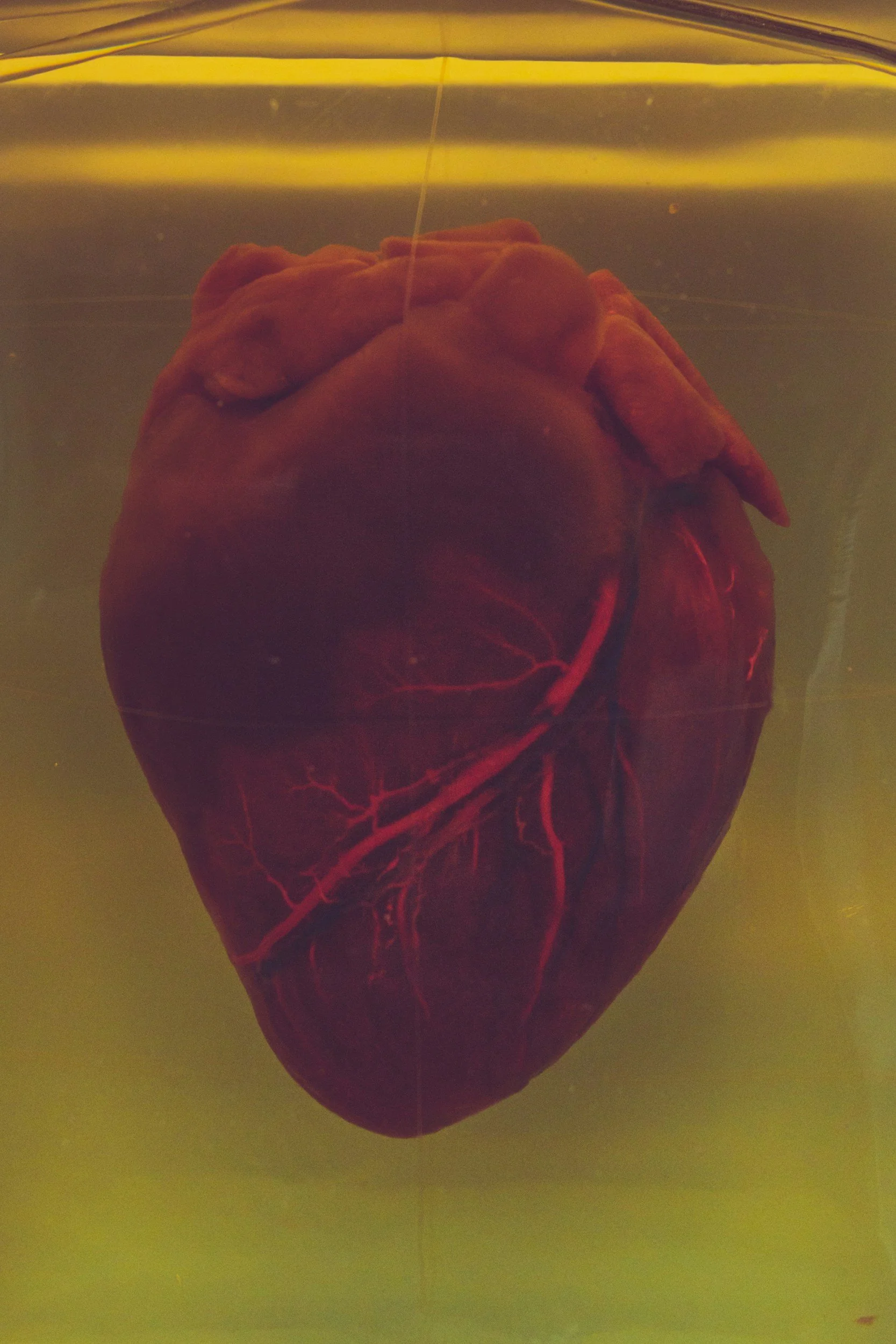

HEART ATTACK SAFETY

Every single year there are 735,000 Americans who suffer heart attacks according to the CDC. Out of that number, 525,000 of them are first-time heart attack victims. Heart disease and heart attacks are an unfortunate reality in our country.

Read More

AUTOMATED EXTERNAL DEFIBRILLATOR (AED)

The list of possible medical emergencies you can experience in life is a long one. A common medical emergency that takes the lives of many people are emergencies that involve the heart. Heart attacks are extremely common; over 725,000 Americans experience a heart attack each year.

Read More

SAFETY TRAINING

The LMK Pipe Renewal safety Committee will provide safety training of the following types.

All employees, as specified are required to receive such safety instructions.

Read More

EMERGENCY ACTION PLAN

LMK Pipe Renewal has made the decision that personal safety takes precedent over company

property in all emergencies. No extreme action should be taken that Threatens personal safety.

Dial 911 in the event of an emergency.

Read More

REPORTING ACCIDENTS

All accidents involving injury or exposure to toxic chemicals must be reported to the Laboratory

Supervisor and the Lab Health and Safety Officer immediately. If an injury results from an

accident, an accident report form must be filled out by the personnel directly involved.

Read More

HURRICANE PREPAREDNESS-RESPONSE PLAN

It is company policy to stop or delay construction activities, 24 to 48 hours prior to landfall

depending on the project’s geographical distance from our closest shop/yard. The only

exception would be for any activity related to prepping or securing the job site for the coming

storm.

Read More

CHEMICAL HANDLING AND REAGENT PREPARATION

Transport and handle bulk chemicals and concentrated reagents with extreme care. Always use

two hands when carrying bottles of acid or large sizes of stock chemicals. Plastic carrying

containers are available for transporting large bottles, which are not safety coated.

Read More

HEAT STRESS

Outside of the direct consequences such as heat stroke, heat stress can cause incidents due to loss of focus or excessive fatigue on the job….

Read More

LEAVE YOURSELF AN OUT

Leave Yourself an Out

All too often individuals are injured at work due to putting themselves into the line of fire or finding themselves in a place where they cannot escape danger. There are many different examples of these types of incidents. From a dropped load falling onto your foot to rear-ending the car in front of you, there are many scenarios like these incidents that are preventable if you leave yourself an out.

Read More

SAFETY ON A NEW JOBSITE

It's important for you to remember that most accidents are caused by carelessness or thoughtlessness--yours, or someone else on the job. When an accident occurs, it is because someone has failed to foresee that it could happen. If you think ahead of the possible hazards likely to confront you, you can plan how to avoid them. When starting work at a new job site, size up the situation and think of ways to prevent accidents and keep the job safe.

Read More

PINCH POINTS AND HAND INJURIES

We use our hands for virtually all work tasks that we do. Because of how often we use our hands, they are put in the line of fire where they can be injured. Hand injuries are the second leading type of injury on the job in the United States.

Read More

HYDRATION: THE IMPORTANCE OF WATER

Water is one of the most important substances on Earth. All plants, animals, and people need water to survive. Water serves important purposes to our bodies and our bodily functions- some of which you may not even be aware of….

Read More

CHEMICAL HANDLING AND REAGENT PREPARATION

Transport and handle bulk chemicals and concentrated reagents with extreme care. Always use

two hands when carrying bottles of acid or large sizes of stock chemicals. Plastic carrying

containers are available for transporting large bottles, which are not safety coated.

Read More

EQUIPMENT MAINTENANCE

Equipment should be inspected prior to use.

Keep equipment maintained. All major equipment is serviced regularly. Smaller appliances

should be checked as necessary.

Read More

FOOD, BEVERAGES, AND SMOKING

Smoking is not permitted.

The consumption of food is not permitted in wetout area.

Beverages are allowed but may only be kept and consumed at "dry" personal desks or computer

stations. Drinking in any work isle or at "wet" benches is strictly prohibited. Beverages are

prohibited in the microbiology laboratory, dishwasher room, chemical storage area and near

fume hoods. Consumption of drinks is discouraged while an analyst is actively performing tests.

Read More

STANDARD OPERATING PROCEDURES: GENERAL SAFETY RULES

Know the safety rules and procedures that apply to the work that is being done. Determine the

potential hazards (e.g., physical, chemical, biological) and appropriate safety precautions before

beginning any new procedure.

Read More